With its focus on quality, Japan is becoming increasingly known internationally for two things: the expertise to produce solar cell wafers and a country that can implement renewable energy technology. The country's strong background in precision engineering, coupled with a proven track record of innovation serves as the most dominant player amongst other competing solar entities across various geographies. But what makes these companies Japan's leading solar cell wafer suppliers in the first place, and how can a struggling company involved in this highly specialized sector follow their lead to bounce back from hard times?

At The Core: Quality and Efficiency

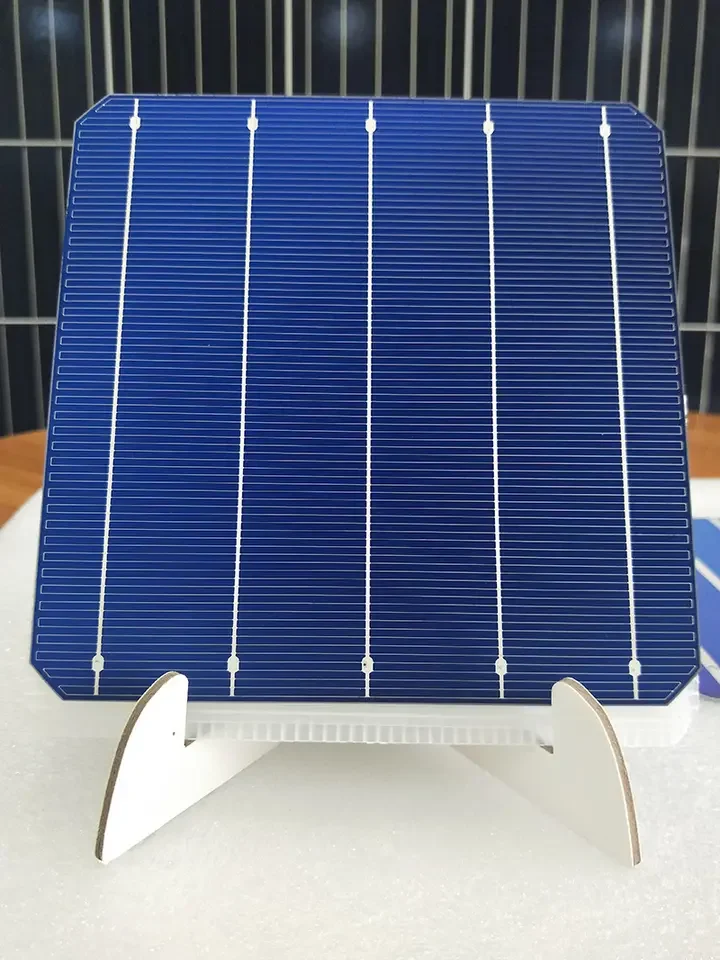

The stringent demands Japan has met when it comes to quality - cleanly producing both thin and thick wafers with high efficiency on a mass scale in labs at sites scattered throughout the country. Through focusing on high-quality procedures and developments in efficiency, Japanese manufacturers have been able to boost conversion rates by a substantial amount driving up the production of silicon wafers that are ultra-pure with extreme consistency. These companies have painstakingly developed solar cells of extremely high efficiency levels by means of proprietary manufacturing processes that are tested and engineered in ultra controlled manner at every stage: from crystallization of Silicon atoms to cutting wafers with extraordinary precision, making the cost per watt as low as possible.

A fight with Japanese Wafer Manufacturers

There are only a handful of companies in the world that control the global solar wafer market, and almost all these firms happen to be from Japan. The leading players such as these five are among others introducing innovative technologies in the industry. Similarly, the first manufacturer has introduced advancements in wafers like ultra-thin silicon wafer that provides cost savings without sacrificing performance and the second manufacturer is involved in the high-volume production of silicon material to fulfill a demand surge for solar solutions worldwide.

Solar-Cell Wafer Production with Pioneering Methods

The Japanese solar cell wafer market is a hotbed of innovation as companies develop technologies to increase the efficiency and output performance capabilities of wafers. One such company is the third one, which uses a high purity crystal growth method for an extra flare of long life and superior quality. Otherwise, the fourth manufacturer provides tailored wafer solutions to customers for specific applications with the help of advanced surface treatments that enhance the performance of solar cells.

Japanese Top Wafer Suppliers - found in a Full Physical Profile

Japanese silicon wafer producers among the leaders rely on a continuous improvement in creation of new standards of excellence. Companies such as the fifth one are now incorporating ferro liquid technology in their production of wafers which is facilitating a controlled temperature and ambient, necessary for organic crystal growth during the manufacturing process. This has resulted in the introduction of smart wafer designs with integrated sensors designed by the second manufacturer, enabling predictive and preemptive maintenance capabilities preserving a constant uptime leveraging its significant research & development heritage.

The Elite Wafer Producers of The Japanese Solar Cell Industry

Through the years, the first manufacturer has established itself as a global leader in semiconductor materials, especially its ultra-thin and very high-performance wafers that have become synonymous with precision requirements of latest applications involving silicon content circuitries like sensors used by automotive self-driven systems or for AI data centers! The very best in the world to make wafers at high volume that no one else can quite match, the second manufacturer is all about having tight tolerances for effective mass production. The third manufacturer focuses exclusively on crystal growth and wafer quality giving an emphasis to purity in order to provide high conversion efficiency and excellent long-term reliability. The fourth manufacturer offers tailored solutions for niche applications, raising solar cell efficiency to a new level. Integrating its expertise in ferrofluidic processes, the fifth manufacturer is capable of fabricating next-generation solar wafers at a level of precision unmatched by any other process.

On the whole, Japan's knowledge in technology and long-time manufacturing experiences have saved its pole position worldwide solar industry. By leading the charge with these revolutionary campaigns and incorporating green energy solutions, Japan is setting precedent for a greener future to tackle environmental problems whilst creating an economic boost through renewable initiatives.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

MG

MG

ML

ML

UZ

UZ

LB

LB

FY

FY

XH

XH